Efficient and Practical Vacuum Coating Production Line for Wood Mouldings

This vacuum coating line is specially designed for the application of water-based primer and UV-curable coating on furniture linear items, door sets, baseboards, picture frames, wall panels and various profiles.

The entire painting process is carried out in a vacuum chamber, and the coating is 100% recycled without any waste, and the highest production efficiency can be achieved.

The vacuum pressure can be adjusted by frequency conversion and can be adjusted to the required film thickness.

The vacuum coater can uniformly coat three sides and four sides of item by one pass. For linear products surface coating work, vacuum coater can achieve maximum productivity.

Working Theory

The coating material is atomized by air vibration causing by the pressure difference between inside of vacuum chamber and outside. Coating is 100% circulated.

- 3 sides or 4 sides are finished by one pass

- 2 coating material types are applicable

- Quick mold change capability for different moulding designs enables easy operation

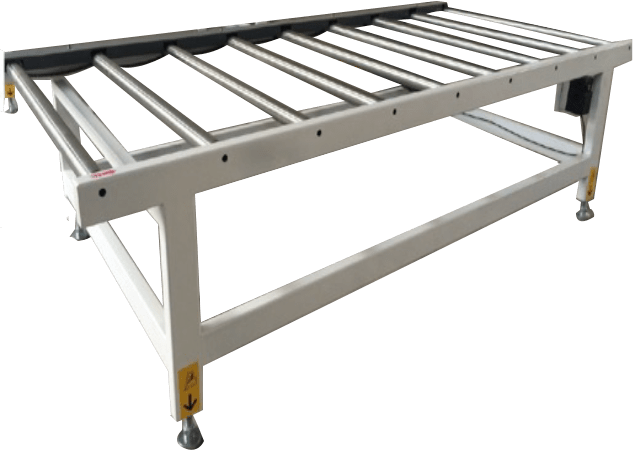

Related Machines